Intimate service comes from the recognition of customers, and proposes high-quality product matching solutions according to customer needs

Product quality comes from rigorous and perfect quality control, and every step is full of our strict sense of responsibility

Exclusive customization comes from personalized configuration solutions, timely and efficient supporting new product development and production

Fast distribution originates from sufficient inventory + processing + fast logistics, and upholds enthusiastic and efficient management

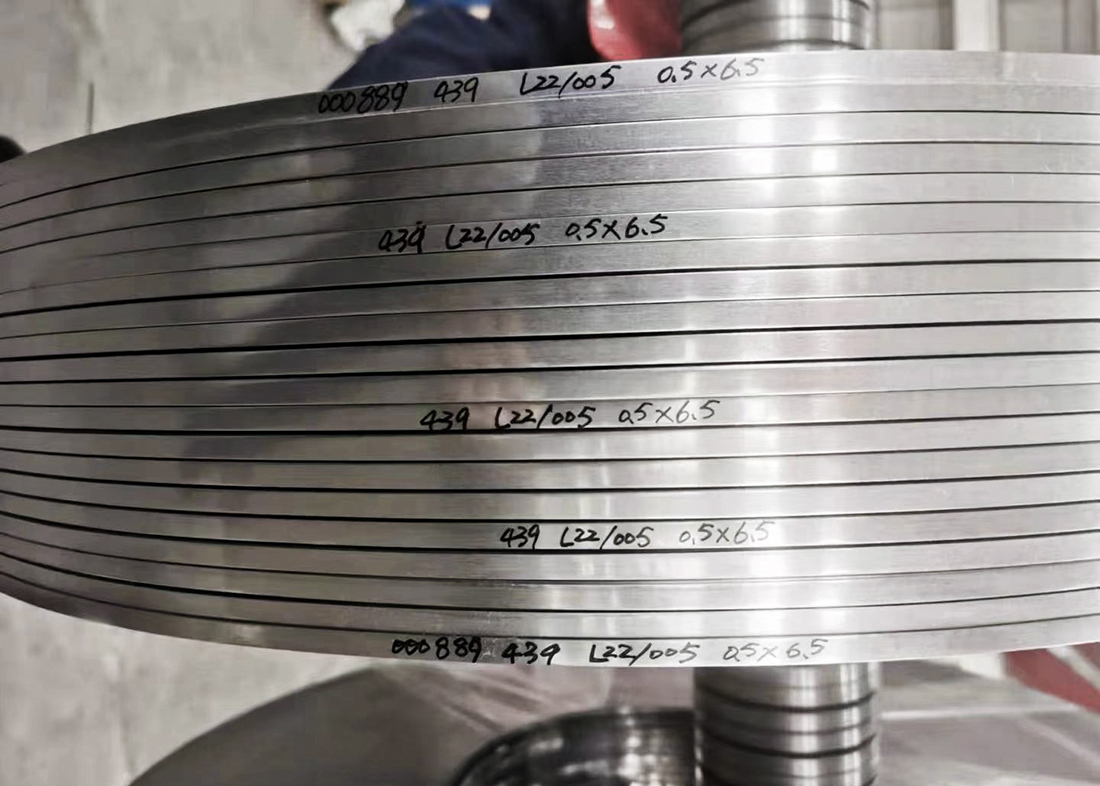

From raw material detection to warehousing registration management, to ensure the overall quality of products

From surface treatment to standard comparison

From material cutting and processing control to re-inspection, packaging and delivery

Every step is full of our strict sense of responsibility

Special material stainless steel is mainly produced with a thickness of 0.02mm-3.1mm and a width of 1mm-1500mm

Relying on the company's domestic and foreign processing equipment and logistics network throughout the country

From customer orders to fit stock screening

Then to processing, production, re-inspection and distribution

Our R&D team has established good cooperative relations with domestic and foreign steel mills

Timely and efficient cooperation with customers for product development

Combined with a Japanese-funded continuous electroplating factory, we have successfully launched gold-plated, silver-plated, nickel-plated and other electroplating products.

Products have broad market prospects and development potential

Stainless steel strips are widely used in factories, mainly due to their excellent comprehensive performance, processing characteristics, and cost advantages. The following analysis is conducted from multiple dimensions: 1、 Material performance advantages: adaptable to complex factory environments 1. Good corrosion resistance Stainless steel strip contains alloy elements such as chromium

As an important form of stainless steel material, stainless steel coils are widely used in industries, construction, food and medical fields due to their unique alloy composition and processing properties. Its core performance advantages are mainly reflected in the following aspects: 1、 Excellent corrosion resistance performance Core reason: Stainless steel coils contain alloying elements

In the exhaust system of automobiles, stainless steel strip has become the core material of key components due to its high temperature resistance, corrosion resistance, high strength, and good formability. The following are its main application scenarios and functional characteristics:

The use of stainless steel coils (usually referring to components or plates processed from stainless steel coils) on shelves is mainly based on their characteristics of corrosion resistance, high strength, easy processing, beauty and durability, which can meet the functional and safety requirements of shelves in different environments. The following are specific reasons and application scenario an

In the automotive industry, different types of cars have differences in design concepts, usage environments, performance requirements, and cost control, which can lead to variations in the use of stainless steel strips. Here are some common differences: 1. Family sedan Appearance decoration: Stainless steel strips are usually used to make body decorative strips, such as window frames, door

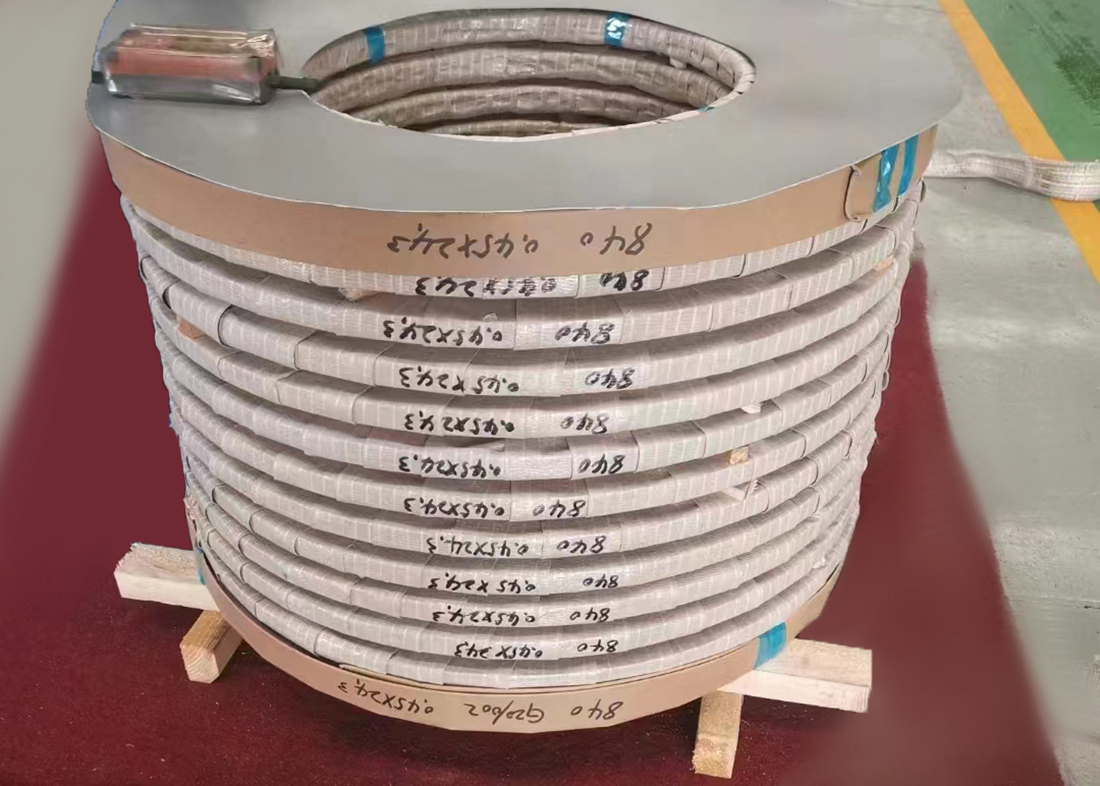

During the transportation of stainless steel coils, attention should be paid to protecting their surface from damage, preventing rust, and ensuring transportation safety, as follows: 1. Packaging protection Stainless steel coils should be properly packaged before transportation. Generally, plastic film, oil paper, or specialized rust proof packaging materials are used for wrapping to preve

Stainless steel strips are widely used in factories, mainly due to their excellent comprehensive performance, processing characteristics, and cost advantages. The following analysis is conducted from multiple dimensions: 1、 Material performance advantages: adaptable to complex factory environments 1. Good corrosion resistance Stainless steel strip contains alloy elements such as chromium

As an important form of stainless steel material, stainless steel coils are widely used in industries, construction, food and medical fields due to their unique alloy composition and processing properties. Its core performance advantages are mainly reflected in the following aspects: 1、 Excellent corrosion resistance performance Core reason: Stainless steel coils contain alloying elements

In the exhaust system of automobiles, stainless steel strip has become the core material of key components due to its high temperature resistance, corrosion resistance, high strength, and good formability. The following are its main application scenarios and functional characteristics:

The use of stainless steel coils (usually referring to components or plates processed from stainless steel coils) on shelves is mainly based on their characteristics of corrosion resistance, high strength, easy processing, beauty and durability, which can meet the functional and safety requirements of shelves in different environments. The following are specific reasons and application scenario an

In the automotive industry, different types of cars have differences in design concepts, usage environments, performance requirements, and cost control, which can lead to variations in the use of stainless steel strips. Here are some common differences: 1. Family sedan Appearance decoration: Stainless steel strips are usually used to make body decorative strips, such as window frames, door

During the transportation of stainless steel coils, attention should be paid to protecting their surface from damage, preventing rust, and ensuring transportation safety, as follows: 1. Packaging protection Stainless steel coils should be properly packaged before transportation. Generally, plastic film, oil paper, or specialized rust proof packaging materials are used for wrapping to preve

WeChat ID:www.novoreg.cn

WeChat ID:www.novoreg.cn